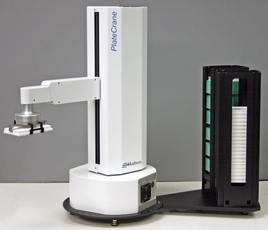

LabLinx™ is Hudson’s unique microplate delivery system (microplate stacker) that allows you to store and deliver plates to any laboratory instrument, automatically. LabLinx is mechanically robust and can turn an ordinary liquid handler into a complete automated workcell. LabLinx microplate stackers are used in assay development, cell biology, bioassay validation, DNA quantification, PCR setup and cleanup and high-throughput drug screening.

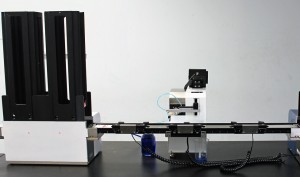

Plates are stored in microplate stacks and moved among the user’s instruments on linkable track segments. “Intelligent” stopping mechanisms are located along the track segments at each instrument’s plate nest positions. There the lab instrument operates on the plate, then, when it‘s finished, LabLinx moves it on to the next lab instrument in the process.

LabLinx operates on many plates simultaneously, each at different stages of the user’s process, resulting in throughput rates that single-arm robot workcells can’t even approach.

LabLinx microplate stacker can service a single instrument, like Hudson’s Micro10x Reagent Dispenser (on the left) for unmatched speed in a simple filling application. Or, LabLinx can move microplates through a series of instruments and systems in a complex workcell, as shown in the video clip below.

FEATURES

LabLinx microplate stacker provides the modularity and flexibility needed by researchers who require their automated instruments to adapt to many different protocols:

- Moves all types of labware: microplates, deepwell plates, tip racks, microtube racks

- Links together any robotics-compatible lab instruments

- Builds a high-speed automated workcell on existing bench space

- Easily reconfigures to accommodate new equipment and assays

- Installs easily within standard laboratory hoods

LabLinx microplate stacker can be configured on available benchtop space or on custom tables. All mechanical and electrical connections between LabLinx modules are self-contained within the system; no complex external control modules are required to operate the system. The portable benchtop design also makes it easier to install LabLinx systems within laboratory hoods or enclosures.

LabLinx microplate stacker was designed specifically for applications in laboratory automation. A mechanically robust and simple design provides reliable walkaway automation. The system is easy to configure and set up, and provides an economical alternative to track-mounted, articulating arm lab automation systems.

LabLinx microplate stacker components easily fit into existing safety hoods without the need to extend outside the hooded environment. LabLinx components, such as the StackLink and TrackLink, provide high-speed, high-capacity plate delivery even for small systems or single instrument automation needs.

Hudson’s RSH-4000 in-line microplate sealer system uses LabLinx technology for plate-delivery and storage.