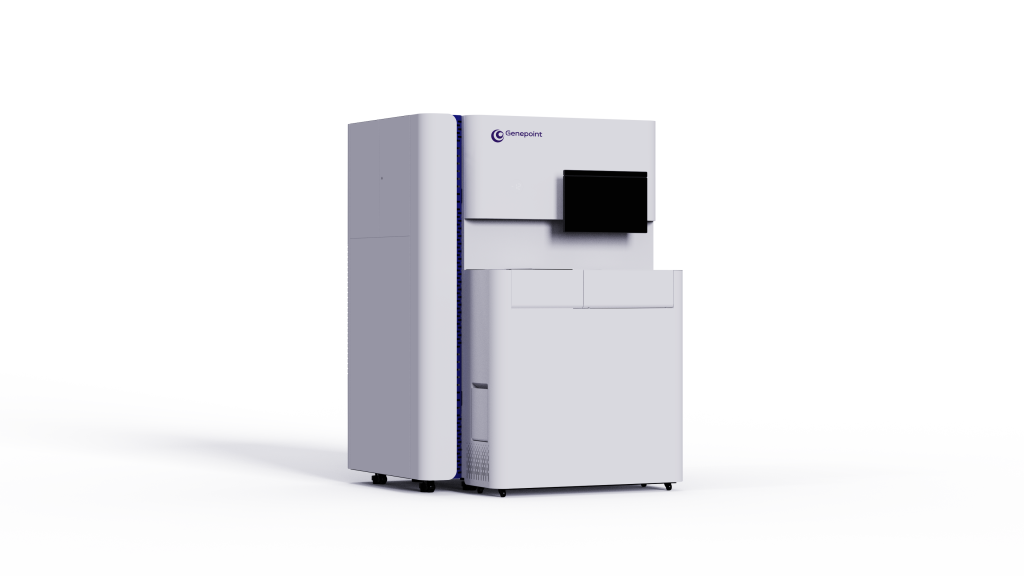

Designed to address the growing need for large-scale storage across diverse sample formats, the BioArc Ultra redefines -80°C automated storage systems, putting energy efficiency and sustainability at the forefront. The BioArc Ultra offers unrivaled sample storage density, an eco-friendly refrigeration system that delivers substantial energy savings, and precision sample retrieval capabilities.

As a space- and energy-saving alternative to manual freezer farms, the Ultra delivers unmatched efficiency with reduced labor requirements and lower running costs. From large-scale sample storage/warehousing and biobanking to biological and vaccine research, manufacturing, and clinical applications, the BioArc Ultra stands ready to meet the diverse needs of today’s dynamic scientific landscape and cold chain logistics.

The new system promises to save space and energy while making great strides in sustainability: delivering eco-friendly technology with zero Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP). The system generates a Total Equivalent Warming Impact (TEWI) that is up to 79% less than the equivalent number of manual freezers.

*Compared to equivalent manual freezers. Estimated using historical averages for electricity costs and assumptions made by Azenta related to your existing equipment and floor plan.

**Zero Global Warming Potential (GWP) and zero Ozone Depletion Potential.

Properties

- Storage density: Boasting the highest storage density on the market, BioArc Ultra maximizes your storage capacity like never before.

- Eco-friendly refrigeration: The cooling system utilizes natural air instead of chemical refrigerants, meaning it presents zero global warming potential.

- Up to 10 picking stations: The option of up to 10 picking stations provides the flexibility to increase throughput and/or labware types.

Automation Interface Module: Directly connect the storage system to an external workcell or interface with an AMR (Autonomous Mobile Robot) through the Automation Interface Module (AIM). - Labware flexibility: The system effortlessly handles diverse labware types, including tubes, vials, bottles, syringes, plates, racks, cryoboxes, and more. Its adaptable design facilitates efficient storage, retrieval, and seamless integration into various lab workflows.

Quality Assurance

The BioArc Ultra maintains sample integrity by keeping innocent (“unpicked/unselected”) samples at storage temperature throughout the picking process.

Other quality assurance features include:

- Minimized thermal disruption: BioArc Ultra employs patented tile wall storage, maximizing reliability and sample temperature stability while eliminating the risk of ice formation. Retrieving samples opens less than 1% of the wall surface area, preventing unnecessary temperature cycling for innocent samples.

- Robotic picking modules: Can perform picking at either -80°C — or for higher throughput — at -20°C. Picking operations are performed outside the sample storage space and separated by an insulated tile wall, so all samples are securely stored at -80°C.

- Sample stabilization: Using a staged storage loader, samples are placed in an input area to stabilize temperature without affecting nearby cold samples. During reformatting or output, operations outside the storage are time-limited to prevent sample warm-up, with prompt return to storage for temperature stabilization, ensuring integrity and minimizing variations.

- Moisture extraction: At extremely low temperatures where moisture instantly turns to ice, the system utilizes a unique Snow Catcher, enabling machines to operate continuously without the need for defrosting procedures that consume cooling power and additional energy.

- Redundancy: With two refrigeration units per bank, the setup ensures redundancy in the event of a unit failure.

- Monitoring: Both temperature and unit alarms are monitored continuously — with 24/7 call center monitoring available.

Store Controller Software

Intuitive, easy-to-use, fully featured Strata™ Store Controller Software is included for effective sample management and inventory control. It provides:

- Sample security: Conducts lifetime inventory and environmental tracking while compiling sample chain of custody and audit trail reports.

- High performance and reliability: Provides full order control, including drag-and-drop order prioritization. Optimizes throughput with more efficient batch workflows and order decomposition.

- Easy to use: Intuitive, information-rich display with modern graphics permits operations with zero special training. Customizable screens permit application-specific workflow presentations.

- Seamless IT integration: Flexible deployment options include active directory integration and encrypted system access passwords. LIMS options include web services API, database, and file-based integration. Accessibility is highly configurable with definable user roles.

- Configurable: Creation of users and roles, gadget and access customization, system level customization.

- Compliance: Strata supports 21 CFR Part 11 compliance.