- Designed and developed with broad compatibility in mind, the tubes perform without compromise in conjunction with automated barcode reading, capping and sample management systems from FluidX and all other industry-recognized manufacturers

- Provides a lifelong and secure chain of custody for samples in biobanks, compound libraries and a broad range of biological and chemical stores, including cryogenic storage

- Developed to exceed the demands of sample security, management and tracking in modern high density storage applications

- Each tube features a permanently laser etched 2D code and human readable number on tube base, allowing compatibility with low throughput manual, semi-automated or fully automated workflows on integrated platforms

- Manufactured using an advanced manufacturing process which results in a one piece tube from high quality virgin polypropylene

Secure sample storage and tracking

- Permanently laser etched 2D code on base and human readable number on the base, ensuring a permanent link between sample and data

- 2D codes readable without removing tubes from racks

- High contrast 2D codes are more reliably readable in frost or condensation conditions

- 100% quality control, each tube is tested to ensure both readability and uniqueness

- Leak tested to ensure sample security

- External thread tubes provide greater working volume than internal thread tubes

- Suitable for sealing with screw caps or TPE septum caps

- Suitable for cryogenic storage*

Capping options

- Automation friendly screw caps provide flexibility to use tubes across a range of industry-recognized automated tube handling platforms

- Deforming compression seal is more effective than a silicone alternative

- Cap and tube manufactured from the same material, preventing differential expansion during freeze-thaw cycles

- Double start thread engages in a maximum rotation of 180°, facilitating automation

- Non-silicone seal means the cap can never be overtightened

TPE septum caps

- A cost effective sealing option for samples that are only accessed occasionally

- Septum caps are supplied in 96-format back mats to facilitate automation

Racking options

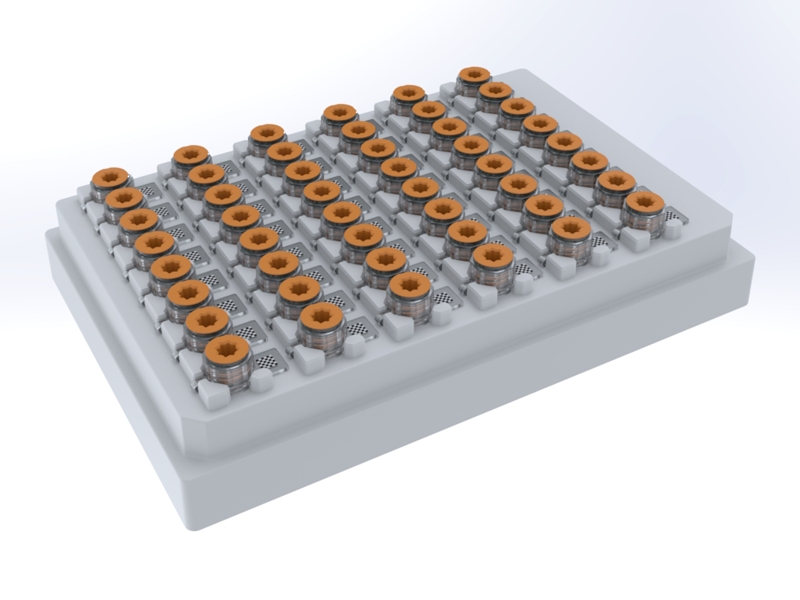

96 format SBS racks

- TwistLock: prevents tubes rotating within the rack to enable automated capping and de-capping of screw caps; provided as standard with the option available to remove

- TubeLock: prevents tubes from falling out, even in lidless racks; useful in manual workflows; activate by applying pressure on the tube top, clicking it into place; tubes can be ordered pre-locked or non-locked

- LidLock: enables racks to withstand a 1m drop test for added sample security

- Automatic rack orientation: a unique 2D code rack identifier readable at the same time as the tube 2D code; for automatic rack orientation and secure sample tracking

- Direct laser etching: a cutout window on the rack sides allow the linear barcode to be read more easily; linear barcodes can be laser etched directly onto racks

Cryo racks

- 136.2mm x 136.2mm PC cryobox rack option available for cryogenic sample storage, holding 196 tubes in 14×14 array

- Open bottom for 2D code decoding on FluidX Perception HD LF reader

- Can be supplied with a unique 2D code identifier which can be read at the same time as the tube 2D code, for more secure sample tracking