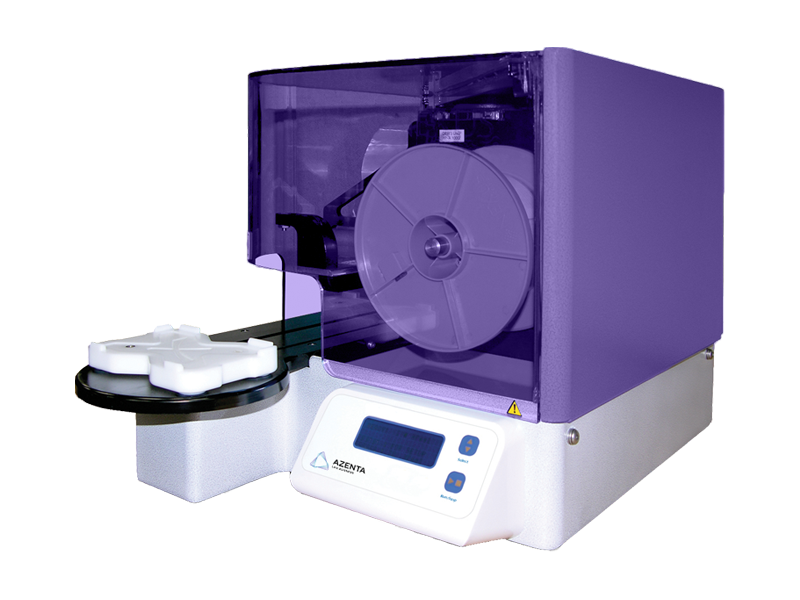

The Automated Plate Seal Remover automatically removes seals from a wide range of microplate types with the single touch of a button. A robust and elegantly-simple automated system, it eliminates the need for repetitive, manual removal of plate seals and enables the adoption of the gold-standard operating model (sealed plates, no lids).

The patented Tape removal medium eliminates the need for mechanical removal mechanisms which are often prone to failure. The Automated Plate Seal Remover is highly reliable and can be used manually or integrated into automated systems with external robotics.

Specifications

Parameter Automated Plate Seal Remover

Seal removal capacity: up to 400 per Removal Tape roll

Seal verification sensor: reflective with sensitivity adjustment

Communication: serial RS232

Motion parameters: Removal Tape adhere time, de-seal speed, plate output orientation, begin peel location

General parameters: auto Removal Tape advance, plate verification, menu language

Weight: 35kg (76lbs)

Power requirements: 115VAC, 4A, 60Hz, 230VAC, 2A, 50Hz

Throughput: up to 200 plate seal removals per hour

Ordering Information

Automated Plate Seal Remover, Compatible with virtually all microplate and seal types

˖ XP-A_230V 230V, version for Europe; 1 unit

Compatible tapes

˖ X-Tape_2000 Removal Tape roll; 5 rolls

Compatible with Virtually all Microplate & Seal Types

Can be used with a wide variety of microplates, including full-skirted PCR plates, low-base microplates and deep-well (up to 2ml) plates

Compatible with a variety of full-plate seals, including heat and pressure applied seals

Uses proprietary Removal Tape to de-seal microplates, up to 400 seal removals per tape roll

Preserves Sample Integrity

Eliminates cross contamination common with manual seal removal techniques

Supports quality control measures requiring samples to be sealed until their moment of use

Holds the plate down whilst the seal is peeled away from the plate, eliminating another contamination issue

Operating mode minimizes plate or seal damage

Integrated seal removal verification feature reduces plate handling errors

Easy to Use, Easy to Integrate

Can be used as a standalone system, or integrated into automated and robotic workflows via Serial RS232 remote interface

One-touch, push-button operation to de-seal plates makes the Automated Plate Seal Remover an ideal standalone device for busy laboratories

Capacity to remove up to 200 plate seals per hour

Robust, time-proven device with hundreds of units placed globally in a range of manual and automated environments