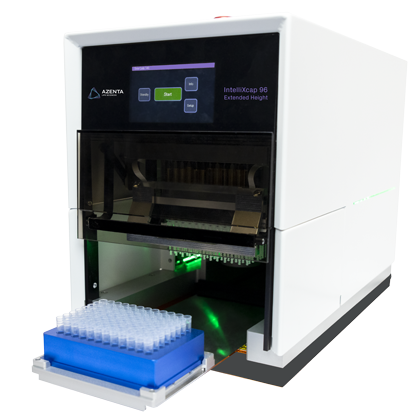

Azenta Life Sciences IntelliXcap Automated Screw Cap Decapper/Recapper 96-format, Extended Height is specifically designed to work with taller 96-format SBS racked tubes. It’s extremely fast and works with multiple sample storage tube types from a range of tube manufacturers in 96 format. Capable of de-capping a complete rack of 96 tubes in as little as 20 seconds.

With the flexibility to work with multiple labware types, the system can decap nasal swabs with integral caps, such as RHINOstic® Automated Swab. It’s ideal for scaling up in swab-based sample workflows where increased throughput requires automation for efficiency and precise handling of samples.

The IntelliXcap combined with the RHINOstic Automated Swab increases throughput while decreasing turnaround times and per-test costs for laboratories using swab sample collection for home kits, multi-analyte respiratory panels, genetic testing, and other types of test kits.

Specifications

| Parameter | IntelliXcap Automated Screw Cap Decapper/Recapper 96-format, Extended Height |

| Dimensions (H x W x D) | 370 x 256 x 464mm |

| Weight | 24kg |

| Ambient operating temperature | 5°C to 40°C |

| Capping/decapping speed | 20-40 sec to decap or to recap a rack of tubes |

Driver & Cap Compatibility

- We provide a wide range of custom made and off the shelf driver cartridges to accommodate your specific labware needs

- The modular design of the system allows you to quickly and easily change the cap driver cartridge and seamlessly swap between tube types, making the instrument the ideal capper/decapper for your automated high throughput workflows

- Due to its flexibility, with one IntelliXcap Automated Screw Cap Decapper/Recapper 96-format, Extended Height instrument you can cap, de-cap and re-cap both internal and external thread tubes

- Many of the 96 format screw cap tubes on the market, including Azenta Life Sciences, LVL, Micronic, Matrix, Nunc, Greiner and swab caps can be processed with IntelliXcap

- Automated Screw Cap Decapper/Recapper 96-format, Extended Height

- Talk to us today: contact an expert, or drop a comment when you request a quote or a demo to let us know what tubes you’re using: we’re happy to come up with a solution cut out to fit your unique application needs

Advanced Automation for Increased Throughput

- Extremely fast, works with multiple sample storage tube types from a range of tube manufacturers

- Suitable for use with 96-format racked tubes

- Capable of de-capping a complete rack of 96 tubes in as little as 20 seconds

- Automation and high speed reduces sample handling time, increasing sample throughput workflow

- Ideal for medium to high-throughput laboratories managing compound libraries, biobanks or other biological samples

Compact, Modular Design for Ultimate Flexibility

- Features a unique, fully automated, interchangeable cartridge cap driver system

- Cartridges allow format change between different tube types in less than 2 minutes

- Simply by fitting the relevant cartridge, IntelliXcap Automated Screw Cap Decapper/Recapper 96-format is compatible with all Azenta Life Sciences sample storage tubes, and support other sample tube ranges available in the market

- Cartridges are available for both internal and external thread screw-cap tubes

- No need for specialist intervention to change cartridge drivers

- Control is via a quick installation, easy-to-use touch panel

Easy to Use, Easy to Integrate

- Quick installation, easy-to-use touch panels bring instant control

- Wide operating temperature range of 5°C to 40°C

- Electric torque control means less persistent wear on cap drivers

- Sample rack stage extension facilitates fully automated workflow integration